When I first heard about Coupi, I was about to finish my minor in Mathematics and my junior year of pursuing a degree in Computer Science. I had already been searching for a summer internship that would allow me to put what I learned during my past three years at UAF to the test.

Through the Alaska Center for Innovation, Commercialization, and Entrepreneurship, I had the opportunity to connect with multiple startups, including Coupi. Some of the things that intrigued me about Coupi was the many ways real-world objects and particles could be represented using the discrete element method (DEM), and their use of Lua, a language that I had enjoyed learning the previous semester during one of my courses. Being an intern for Coupi would also give me the chance to work with others in my field of study. After meeting with Dr. Johnson, the CEO of Coupi, and talking about Coupi and the goals they were trying to achieve, I knew I wanted to be a part of Coupi’s team.

Learning the Software and Bug Testing

My first few weeks at Coupi were spent reading through and updating the user manual, which had not been updated much since the previous summer despite all the changes that had been made to the software. I used it to help me learn to use Coupi’s graphical user interface called Cime. Once I became familiar with Cime, I began testing the software for bugs on the Mac operating system. My main focus while testing was to test the capabilities of Cime’s dynamic particle generator, which was a new feature at the time.

My favorite part about bug testing was the different views it gave me on the software. Instead of asking myself “how does this function”, I had to change my perspective and ask, “how can I break this functionality”. I also had to imagine how a customer or someone with no experience using our software would have difficulties understanding or using our software. To get the bugs resolved, the other interns and I had to communicate back and forth with the development team in Ukraine. This proved to be difficult at times because the eleven-hour time difference between Alaska and Ukraine could cause delays in updating the software and making progress. Despite some difficulties, I feel as though the interns and the development team communicated well in order to make progress and improve the software.

Real-World Applications

The two biggest projects that I contributed to over the course of my internship were running rotary press and tumble blender simulations. The rotary press simulations were used to compare how different aspects of tablet formation in the pharmaceutical industry can cause particles to stick to the punch and reduce the efficiency of the punch and the stability of the tablet. Some of the aspects that we compared were adhesion and cohesion pressures of the active pharmaceutical ingredients (API), excipients, and the punch and die walls, as well as the use of different excipients and API, and the use of different punch pressures.

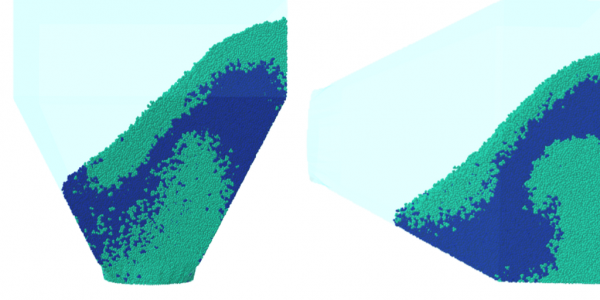

As for the blending simulations, I ran simulations of blenders commonly used in the pharmaceutical and food industries. Three different types of tumble blenders using a variety of rotation velocities, particle sizes, and particle shapes were used to compare how well the particles will mix. Once the mixture was blended uniformly, the mixture would be released into a tube to see where and how segregation of particles began to develop.

Even though I mostly worked with software, I also helped prepare for presentations. I created graphs for our data from the rotary press trials. One of the other interns and I had to write an abstract for our blending simulation research on the effects of particle size and shape on the uniformity of a mixture and the occurrence of segregation of the particle mixture as it flows through a tube. We then helped to create a poster on blending simulations and RSD calculations by gathering images of our simulations and writing about the blending and RSD calculation processes.

Takeaway

Working for a startup gave me exposure to experiences outside of working with software that I do not think I would have had with other internship opportunities. For starters, the other interns and I worked directly with Dr. Johnson and Dr. Kulchitsky, the CEO and CTO of Coupi, to set tasks, develop projects, work on research and presentations, and meet deadlines. Working with our developers in the Ukraine gave me an inside look at the benefits and difficulties of international communication. I also gained insight on the marketing side of Coupi when I had to present the goals of Coupi, the capabilities of our software, and the purpose of our blending and rotary press simulations to UAF alumni.

While being an intern for Coupi, I gained useful experience in software development that built off of what I had learned during my time at UAF and it gave me additional opportunities that I would not have had in class. Overall, I am thankful for the opportunity to be a part of the Coupi team as an intern, and to be able to see Coupi’s software grow so much in the few months that I have been here. I hope to see Coupi’s world-changing software continue to grow and provide more opportunities like my internship to students in the future.