For the past two years, Coupi has worked with interns to help test our Poyphysica discrete element method (DEM) computer-aided engineering model (CAE) and work with our team to simulate real-world processes. One of these simulations is related to the pharmaceutical industry. In the pharmaceutical industry, it is important to create a uniform blend powder of active pharmaceutical ingredients with the inert ingredients (excipients) used in making tablets, which can be difficult as particles of different size and shape tend to segregate into clusters. Coupi recently simulated the blending performance of intermediate bulk containers (IBC) blenders as a function of powder particle dimensions and shape using Polyphysica.

Simulating Powder Flow within IBC Blender

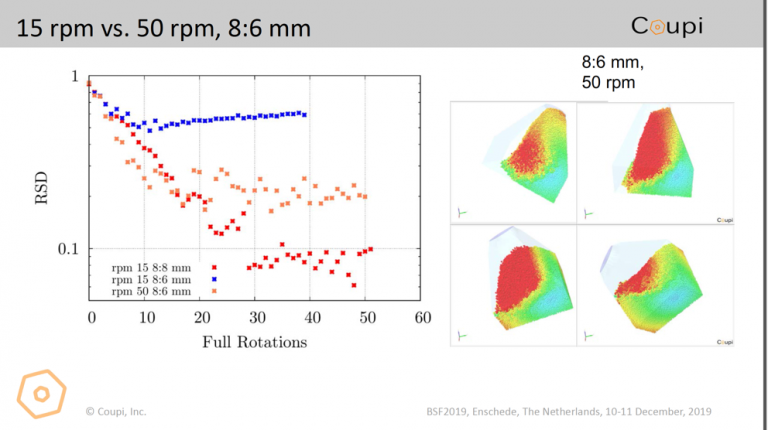

Simulation results presented by Anton Kulchitsky (Coupi CTO) at BSF-EU 2019 Blending Simulation Forum Europe demonstrated that differences in powder particle sizes and shapes, IBC blender shape, rotation rate, and the number of rotations all affect the severity of particle segregation in the powder. The powder flow within an IBC blender depends on its rotation rate at relatively slow rotation rates (e.g., 15 rpm) particles tend to roll down a powder slope that develops as the IBC blender is rotated (counterclockwise in the figure). As the IBC rotation rate increases the flow of particles evolves from rolling to cascading then cataracting and centrifuging as the rotation forces particles against the walls of the IBC. Simulations of binary (two different specie particles indicate that higher speed rotations improve blending performance for particles of different size or shape. IBC blending of binary spherical particles of the same size blend well at all IBC rotation speeds after about 25-30 full rotations (red) as shown by decreasing RSD (relative standard deviation) with for rotation number. Different sized binary particles (8 mm and 6 mm spherical particles) show poor blending at low IBC rotation speed (15 rpm, blue) with improved blending at high IBC rotation rates (orange).

Learn More About Coupi

To learn more about our interns’ experiences at Coupi. Visit our intern blog. To learn more about Coupi, the types of projects we work on and our software, we invite you to reach out to us.

Coupi, Inc. specializes in developing physics-based DEM models of granular materials, and their interaction with fluids, solids, and engineered equipment and infrastructure on Earth and in space for CAE applications. Our team consists of specialists in engineering, physics, mathematics, computer science, and granular media mechanics. Coupi software capabilities are continuously upgraded to improve simulation accuracy of physical world engineering and science problems.

Coupi software is available for direct purchase to enable customers to build industry-specific simulations. Coupi consulting services can work with customers to develop applications for their use to solve specific problems or to provide a complete problem solution.